slotting machining - slotting machine typesslotting machining - slotting machine types Descubra a plataforma slotting machining - slotting machine types, Slot machining, a specialized slotting area machining withinmachining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. What is Slot Machining? .

slotting machining - slotting machine types Slot machining, a specialized slotting area machining withinmachining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. What is Slot Machining?

jogo do bicho agreste de hojeloteria agreste slotting machining - slotting machine types, Na Resultado Fácil você encontra Resultado jogo do bicho de Pernambuco de 10, 11, 12, 13, 14, 15, 16, 17, 18, 19 e 20 horas de hoje, ontem e de outros dias. Exibimos diariamente os .

Veja mais. Transferir e instalar o TikTok Asia - TikTok APK - Versão: 31.7.4 - com.ss.android.ugc.trill - TikTok Pte. Ltd. - App para Android 4.4, 4.3, 4.2, 4.1 / Android .

Descubra a plataforma slotting machining - slotting machine types, Slot machining, a specialized slotting area machining withinmachining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. What is Slot Machining? .

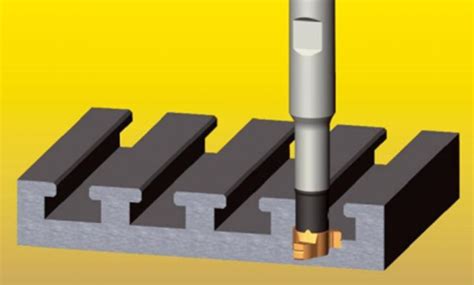

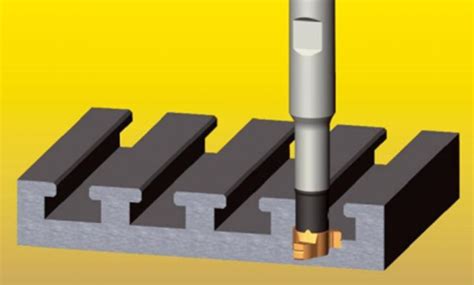

slotting machining*******Machining a groove or slot, often called full slotting, involves three machined faces: Slots closed at both ends are pockets, requiring end mills that can work in the axial direction; Full slotting with an end mill is a demanding operation. The . Slot machining, a specialized area within machining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. What is Slot Machining? Slot milling is one of the highly useful machining techniques that comes in handy when cutting slots. In this article, we dive deep into slot machining, discussing what it is, the cutters it requires, and its operation types.The slotting machine is used to machine grooves, keyways, slots of various shapes, internal and external gear cutting etc. processes. A slotter can be useful in any type of machining where .

slotting machining Slot milling is the process of creating slots or channels in a part using a special rotating tool. The slots or channels can have a rounded or rectangular profile, but this is based on the shape of the end mill. Slot milling is . Slot milling, also referred to as groove milling, is a process that involves the use of a cutter to cut slots or channels on a workpiece. This process is used in many fields of engineering to produce accurate geometries, . Slot milling is a machining operation that uses a rotating tool that has multiple cutting edges to form grooves in a workpiece. This process is used to produce components with precise slots, keyways, or channels.

slotting machining Slot milling is an essential machining operation used across different industries to make slots, grooves, and pockets on a workpiece.

slotting machining Slot machining is one of the most versatile and widely used CNC milling processes in machining grooves with limitless shapes and sizes. This process uses various slotting tools to make precise pockets, grooves, or slots .

slotting machining Slot milling is a fundamental process in CNC machining, used to create slots and grooves in workpieces. It involves using a milling cutter to remove material, creating precise slots of various shapes and sizes. This .

Machining a groove or slot, often called full slotting, involves three machined faces: Slots closed at both ends are pockets, requiring end mills that can work in the axial direction; Full slotting with an end mill is a demanding operation. The axial cutting depth should be generally reduced to around 70% of the edge length. Slot machining, a specialized area within machining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. What is Slot Machining?

Slot milling is one of the highly useful machining techniques that comes in handy when cutting slots. In this article, we dive deep into slot machining, discussing what it is, the cutters it requires, and its operation types.The slotting machine is used to machine grooves, keyways, slots of various shapes, internal and external gear cutting etc. processes. A slotter can be useful in any type of machining where the vertical tool movement is required and considered advantageous for the purpose. Slot milling is the process of creating slots or channels in a part using a special rotating tool. The slots or channels can have a rounded or rectangular profile, but this is based on the shape of the end mill. Slot milling is a popular method in the manufacturing world. You can achieve all manner of shapes with slot milling.

Slot milling, also referred to as groove milling, is a process that involves the use of a cutter to cut slots or channels on a workpiece. This process is used in many fields of engineering to produce accurate geometries, for example, keyways or grooves.

Slot milling is a machining operation that uses a rotating tool that has multiple cutting edges to form grooves in a workpiece. This process is used to produce components with precise slots, keyways, or channels. Slot milling is an essential machining operation used across different industries to make slots, grooves, and pockets on a workpiece.

Slot machining is one of the most versatile and widely used CNC milling processes in machining grooves with limitless shapes and sizes. This process uses various slotting tools to make precise pockets, grooves, or slots in different components, meeting strict quality standards and tight tolerances.

Slot milling is a fundamental process in CNC machining, used to create slots and grooves in workpieces. It involves using a milling cutter to remove material, creating precise slots of various shapes and sizes. This technique is crucial in many industries, from aerospace to automotive, where precision grooves are mandatory.

Machining a groove or slot, often called full slotting, involves three machined faces: Slots closed at both ends are pockets, requiring end mills that can work in the axial direction; Full slotting with an end mill is a demanding operation. The axial cutting depth should be generally reduced to around 70% of the edge length.

Slot machining, a specialized area within machining, employs techniques like end milling and face milling to create precise slots in materials using various milling cutters. What is Slot Machining? Slot milling is one of the highly useful machining techniques that comes in handy when cutting slots. In this article, we dive deep into slot machining, discussing what it is, the cutters it requires, and its operation types.

The slotting machine is used to machine grooves, keyways, slots of various shapes, internal and external gear cutting etc. processes. A slotter can be useful in any type of machining where the vertical tool movement is required and considered advantageous for the purpose. Slot milling is the process of creating slots or channels in a part using a special rotating tool. The slots or channels can have a rounded or rectangular profile, but this is based on the shape of the end mill. Slot milling is a popular method in the manufacturing world. You can achieve all manner of shapes with slot milling. Slot milling, also referred to as groove milling, is a process that involves the use of a cutter to cut slots or channels on a workpiece. This process is used in many fields of engineering to produce accurate geometries, for example, keyways or grooves. Slot milling is a machining operation that uses a rotating tool that has multiple cutting edges to form grooves in a workpiece. This process is used to produce components with precise slots, keyways, or channels. Slot milling is an essential machining operation used across different industries to make slots, grooves, and pockets on a workpiece.